When it comes to printing designs on clothing, two methods rule the roost: Direct-to-Garment (DTG) and Screen Printing. Each has its unique advantages and drawbacks, and understanding these can help you choose the right technique for your needs. This article is your comprehensive guide to DTG and Screen Printing, providing an in-depth comparison to aid your decision-making process.

What is DTG Printing?

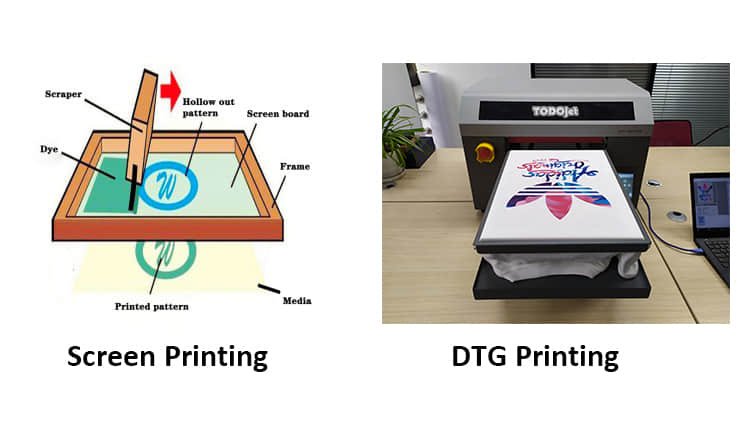

DTG, or Direct-to-Garment, is a printing technique that works almost like a standard paper printer. Images are uploaded to a computer, and a printer injects water-based ink directly into the fibers of the garment. This method results in high-quality prints, with the pattern feeling as if it’s woven into the fabric.

What is Screen Printing?

In contrast, Screen Printing is a more traditional method, where each color in the design requires a corresponding screen template. A squeegee is used to push the ink and print the design onto the item, creating a pattern that attaches to the surface of the clothes. The results are thicker prints with a more tactile, glue-like feeling.

DTG vs Screen Printing: Which is Better?

The answer to this question depends on various factors, including cost, production time, color and print effects, comfortability, fabric and position restrictions, durability, and environmental impact. Let’s dive into these aspects one by one.

Cost and Minimum Order Quantity (MOQ)

Screen Printing cost consists of the plate-making fee and the printing labor charge. For orders above 500 pieces per item, screen printing is the most cost-effective option.

On the other hand, DTG charges based on the printed area, regardless of the number of colors in the graphic. It also allows for very small MOQ, making it an excellent choice for print-on-demand in the market.

Production Time

For small and rush orders, DTG shines due to its fast operation. Screen Printing, though slower initially due to the need for screen template making, can be faster for large orders once the templates are ready.

Color and Print Effects

Screen Printing struggles with color-rich pattern printing due to separate plates and manual color mixing. DTG, however, can handle any number of colors, producing prints that are more vibrant, clear, and consistent.

Comfortability

DTG prints are more comfortable than Screen Prints. The ink is directly injected into the fabric, making it breathable and soft. In contrast, Screen Printing produces a thicker, less comfortable result as the ink rests on the surface of the clothes.

Fabric and Position Restrictions

DTG works best on 100% cotton, while Screen Printing can handle a variety of fabrics. Also, Screen Printing can print on specially shaped items, unlike DTG.

Durability

Screen Prints are more durable than DTG prints, which can fade after many washes. Screen Printing, with its thicker ink, is more suitable for garments requiring frequent washes or long storage, such as sportswear and business uniforms.

Environmental Impact

DTG is more environmentally friendly than Screen Printing. It uses water-based inks that are biodegradable and doesn’t pollute the environment. Screen Printing, however, uses polluting inks and requires large amounts of water and detergents, which have a more significant environmental impact.

Material Considerations

Both DTG and Screen Printing have different capabilities when it comes to the type of material they can work with. DTG printing works best on 100% cotton. However, it doesn’t perform as well on other materials like polyester1. If you’re looking to print on a variety of materials, Screen Printing might be the better option as it can handle cotton, polyester, denim, and more.

Design Complexity and Color

If your design is highly intricate, involves many colors, or contains complex gradients, DTG printing is likely the better choice. As mentioned earlier, it can manage any number of colors, producing prints that are vibrant, clear, and consistent. Screen Printing, on the other hand, is better suited for simpler designs with fewer colors due to the need for separate plates and manual color mixing.

Longevity and Durability

If you want your design to last as long as possible, Screen Printing is the superior option. The prints are thicker and can withstand frequent washes without fading. DTG prints, while still durable with proper care, can start to fade after numerous washes.

Environmental Impact

For those concerned about the environmental impact of their printing process, DTG is the more environmentally friendly choice. It uses biodegradable, water-based inks and precisely controls the amount of ink used, reducing waste. Screen Printing, on the other hand, uses inks that are more polluting and requires larger amounts of water and detergents.

Turnaround Time

The turnaround time for your order also plays a role in determining the best printing method. For small and rush orders, DTG’s fast operation makes it the superior choice. However, for larger orders, Screen Printing can be faster once the initial screen templates are created.

In conclusion, the choice between DTG and Screen Printing depends on the specifics of your project. Carefully considering each aspect of your printing needs will help you make the right decision.