Air compressors are essential tools for powering a wide range of pneumatic tools and applications, from drilling and sandblasting to spray painting and wrenching. However, one major drawback of air compressors is the noise they generate, which can be loud and disturbing, especially in compact and shared working spaces.

If you’re looking for ways to minimize the noise of your air compressor and create a peaceful working environment, read on as we explore the best soundproofing techniques and materials.

Soundproofing Techniques for Air Compressors

1. Acoustic Foam

Acoustic foam is one of the most popular soundproofing materials used for air compressors and other noisy equipment. It consists of open-celled foam panels that absorb and diffuse sound waves, reducing noise levels by up to 30 decibels. To use acoustic foam for soundproofing your air compressor, you can create a custom-sized foam wrap or cover for the compressor or attach foam panels to the walls of your workshop or garage to absorb noise from multiple sources.

2. Vibration Pads

Another effective soundproofing technique for air compressors is using vibration pads. Vibration pads are made of dense rubber or cork materials that absorb vibrations and prevent them from transmitting through surfaces. By using vibration pads under your air compressor, you can minimize the amount of noise that is transmitted through the ground or foundation of your workshop or garage.

3. Enclosure

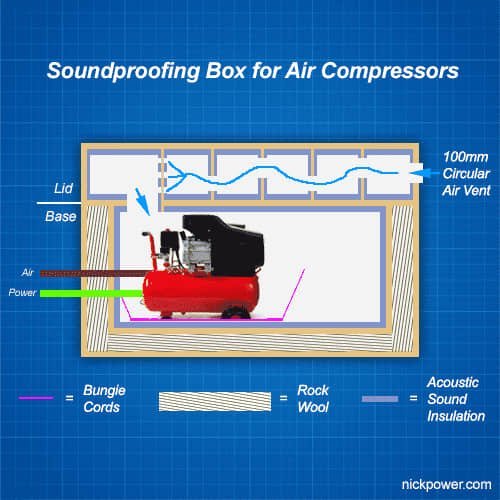

One of the most efficient and comprehensive soundproofing techniques for air compressors is enclosing the compressor in a soundproof enclosure. A soundproof enclosure is a box-like structure made of sound-absorbing materials, such as acoustic foam or fiberglass insulation, that encases the air compressor and muffles the sound it generates. Enclosures come in various sizes and shapes, and you can either buy a ready-made enclosure or build one yourself based on your specific needs.

Best Materials for Air Compressor Soundproofing

While the soundproofing techniques mentioned above can make a significant difference in reducing air compressor noise, the choice of materials used is just as important. Here are some of the best materials for air compressor soundproofing:

1. Acoustic Foam

As mentioned earlier, acoustic foam is a popular sound-absorbing material that effectively dampens sound waves. It comes in different types, sizes, and densities, depending on your specific needs.

2. Fiberglass Insulation

Fiberglass insulation is another common soundproofing material used for air compressors and other equipment. It consists of thin strands of glass fibers that trap sound waves and reduce their intensity.

3. Mass Loaded Vinyl

Mass loaded vinyl is a heavy, flexible sheet made of vinyl and barium sulfate that acts as a sound barrier. It can be used as an additional layer in soundproofing enclosures or wraps for air compressors.

Conclusion

In conclusion, soundproofing your air compressor is crucial to minimize noise levels and create a peaceful working environment. By using soundproofing techniques such as acoustic foam, vibration pads, and enclosures, and choosing the best materials like fiberglass insulation and mass loaded vinyl, you can effectively reduce air compressor noise and improve your overall work experience.