When it comes to maintaining your air compressor, the choice between OEM (Original Equipment Manufacturer) parts and aftermarket parts can be a crucial one. This article will delve into the pros and cons of both options, helping you make an informed decision that suits your needs and budget.

Understanding the Importance of Warranties

Every air compressor manufacturer offers a warranty on their product. To maintain that warranty, you must follow their maintenance schedule using all OEM parts and sample the compressor lubricant during a predetermined warranty period. If a problem arises during the warranty period, it is critical to have copies of your records. That includes receipts, oil sampling results, and maintenance logs. Your factory service center will need this information to submit a claim and it is recommended to create a maintenance log for your equipment.

Tips for Maintaining a Warranty on OEM Tools

- Use machine as factory intended

- Register your machine online with the factory

- Follow recommended maintenance schedule

- Use OEM parts & lubricant

- Perform Oil Sampling

- Keep records of all service visits

The Case for Aftermarket Parts

Here’s the key — once your tools have surpassed their standard warranty period, using OEM parts is no longer necessary. Aftermarket parts are available and can save your company a substantial amount of money, in some cases between 200% and 300%.

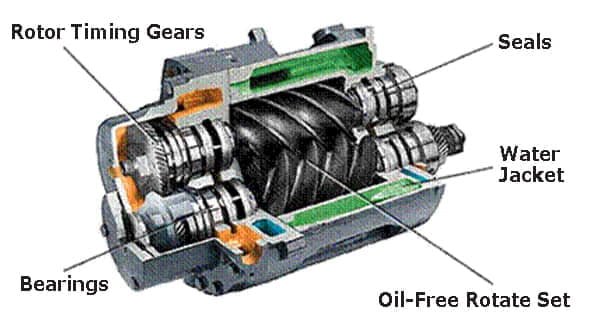

Not all parts will have an aftermarket version. Air filters, oil filters, separator elements, hoses, fuses, and other “consumables” will most likely have an aftermarket cross-over option. The more “internal” parts may not. Items such as motor components, temperature probes, and control panels will likely need a direct factory replacement to ensure efficient and accurate operation.

Benefits of Aftermarket Parts

- Maintenance costs (regular scheduled service visits) are reduced

- Parts are more readily available

- Aftermarket parts are direct replacements

Conclusion

When available, switching to aftermarket parts is a safe change. Many customers are cautious to switch over despite having many reputable companies at their disposal which produce durable and long-lasting aftermarket parts. Compressor World recommends using aftermarket parts after the warranty period. Use the savings and buy a new air dryer, additional air storage tank or put it aside for a new energy efficient variable speed compressor.

FAQs

- Why is it important to maintain the warranty on OEM tools?

To maintain the warranty, you must follow the manufacturer’s maintenance schedule using all OEM parts. This ensures that any problems that arise during the warranty period can be addressed by the manufacturer. - When is it advisable to switch to aftermarket parts? Once your tools have surpassed their standard warranty period, using OEM parts is no longer necessary. Aftermarket parts can save your company a substantial amount of money.

- Are all parts available in aftermarket versions? Not all parts will have an aftermarket version. While consumables like air filters, oil filters, and separator elements often have aftermarket options, more “internal” parts like motor components, temperature probes, and control panels may not.

- What are the benefits of using aftermarket parts? Aftermarket parts can reduce maintenance costs, are more readily available, and are direct replacements for OEM parts.