Hey there! Have you ever wondered what keeps the industrial world running smoothly? One of the unsung heroes is the rotary screw air compressor. These bad boys are the backbone of many industrial applications. So, let’s roll up our sleeves and take a closer look at what makes them tick.

The Basics: What Are Rotary Screw Air Compressors?

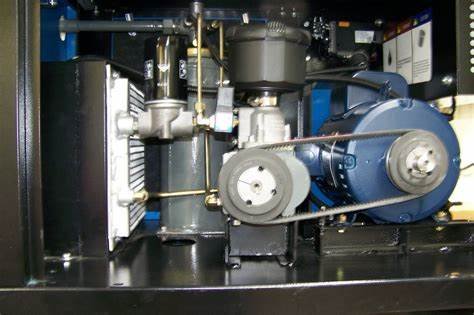

First things first, let’s break it down. Rotary screw air compressors use two helical screws, known as rotors, to compress air. They turn in opposite directions, trapping air between them – pretty neat, huh? They’re part of the positive displacement compressor family, which means they increase pressure by reducing volume. And guess what? They’re darn good at it!

The Dynamic Duo: Lubricated and Oil-Free

There are two types of rotary screw compressors: lubricated and oil-free. The lubricated ones are more popular because they’re cheaper. But sometimes, you need your compressed air to be as pure as a mountain spring. That’s where oil-free compressors come into play.

Advantages: Why They Rock

These compressors are like the reliable friend who always shows up when you need them. They have a simple design, which means they’re not just easy to use, but also easy on the wallet. Plus, they’re efficient and have few moving parts, which means less maintenance – and who doesn’t love that?

But wait, there’s more! They come with manual controls and system regulators, ensuring top efficiency no matter the output level. It’s like having a personal trainer for your compressor!

Disadvantages: No One’s Perfect

Now, let’s not put our rose-colored glasses on; these compressors have their downsides. One of the main issues is the limited airend life. After about 20,000 hours of operation, they might need some TLC and have to be taken back to the service shop. And let’s be honest, nobody likes downtime.

When Are They the Right Fit?

If your application requires 15 horsepower or more, rotary screw compressors are your best bet. However, they’re not fans of extreme environments, so it’s best to keep them somewhere nice and cozy. Also, consider your maintenance and lubrication preferences before making a choice.

Conclusion

Rotary screw air compressors are like the trusty steed of the industrial world. With their efficiency, reliability, and range of options, they’re hard to beat. Just make sure to weigh the pros and cons to find the perfect fit for your needs.

FAQs

Q1: What are rotary screw air compressors?

A: Rotary screw air compressors use two helical screws to compress air. They are known for their efficiency and are widely used in industrial applications.

Q2: What’s the difference between lubricated and oil-free rotary screw compressors?

A: Lubricated compressors use oil in the compression process, making them cheaper. Oil-free compressors don’t use oil, making them ideal when you need pure compressed air.

Q3: What are the advantages of rotary screw air compressors?

A: They are efficient, have a simple design, require less maintenance, and come with manual controls and system regulators for optimal performance.

Q4: Are there any disadvantages to using rotary screw air compressors?

A: Yes, they have a limited airend life and need to be serviced after about 20,000 hours of operation.

Q5: When should I use a rotary screw air compressor?

A: They are best for applications requiring 15 horsepower or more and should be used in environments that are not too harsh or extreme.