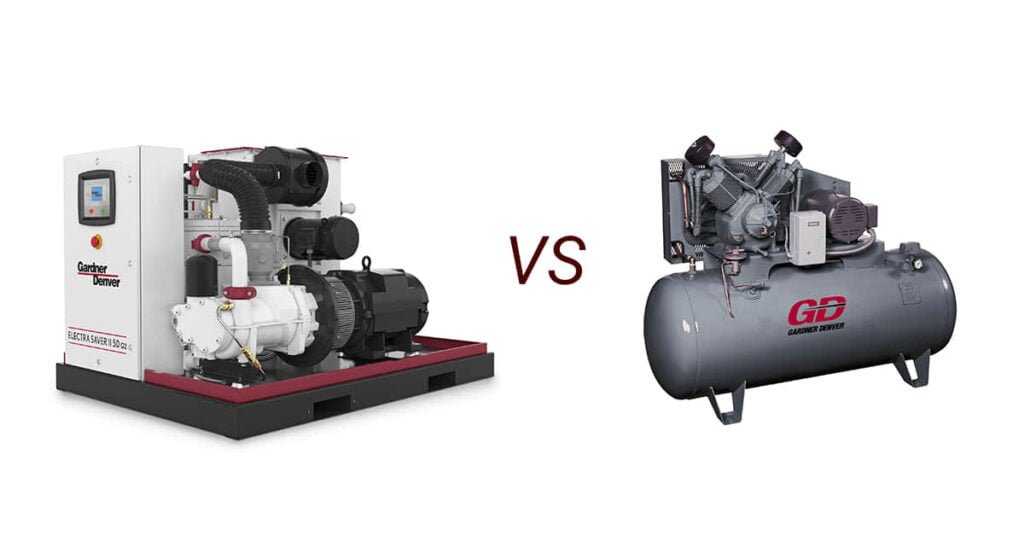

Ah, the age-old question: Rotary Screw or Reciprocating Air Compressors? It’s like choosing between coffee and tea, each has its own charm. Air compressors are indispensable in many industries, but deciding between a rotary screw compressor and a reciprocating air compressor can be a head-scratcher. Don’t worry, we’re here to help you unravel this mystery!

Power: The Heart of the Matter

When it comes to power, rotary screw air compressors are the big guns. They are best suited for applications requiring high power output, generally anything above 15 horsepower. On the other hand, reciprocating air compressors are the little engines that could, ideal for lower power outputs, typically below 15 horsepower. Their simplicity and reliability make them a favorite, even in harsh environments.

Maintenance: Keeping Things Running Smoothly

Rotary screw air compressors are like the low-maintenance friend. They mainly need attention for their oil/air separator, filters, and oil changes. Reciprocating air compressors, on the other hand, require a bit more TLC. But hey, good things come to those who maintain!

Lubrication: Slippery When Wet

Lubrication is key in the life of a reciprocating air compressor. It helps minimize wear and tear, keeping your compressor running longer. However, there’s a choice to be made between lubricated and non-lubricated models. Non-lubricated models are a tad more expensive upfront, and maintenance can be four times higher than their lubricated counterparts.

Conclusion

Choosing between rotary screw and reciprocating air compressors is no small feat. It’s essential to consider your power needs, maintenance preferences, and lubrication options. Both types have their own set of advantages, so weigh your options carefully. And remember, the right choice is the one that best suits your needs.

FAQs

Q1: When should I choose a rotary screw air compressor?

A: Choose a rotary screw air compressor if your application requires high power output, typically above 15 horsepower.

Q2: What are the maintenance considerations for rotary screw air compressors?

A: Maintenance for rotary screw air compressors is mainly restricted to the oil/air separator, filters, and oil changes.

Q3: What are the differences between lubricated and non-lubricated reciprocating air compressors?

A: Lubricated reciprocating air compressors use oil in the compression cylinder which minimizes wear, while non-lubricated do not. Non-lubricated models are more expensive upfront and have higher maintenance costs.

Q4: What type of air compressor is best for harsh environments?

A: Reciprocating air compressors are ideal for harsh environments due to their simple design and wide range of operation.

Q5: What are the power output levels of rotary screw air compressors?

A: Rotary screw air compressors are best for high power output levels and can be regulated to match the plant’s power needs.