As someone who uses an air compressor, you understand how important it is to have it functioning correctly. Air compressors are essential tools for many people, and they are commonly used in workshops, construction sites, and in households. However, they can experience problems from time to time. This guide aims to provide you with easy fixes and troubleshooting tips for some typical air compressor issues.

Understanding How An Air Compressor Works

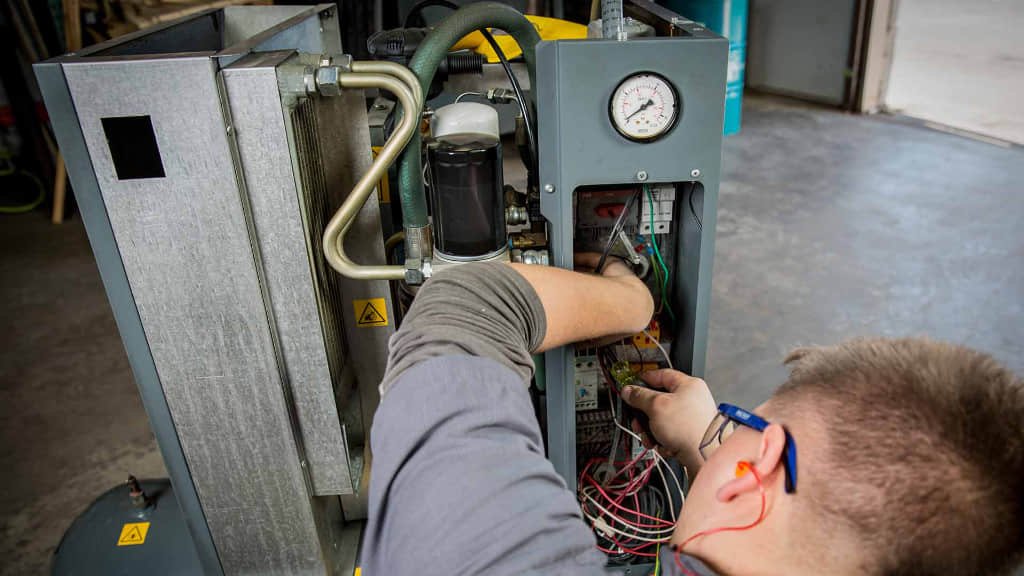

Air compressors manipulate air to create high-pressure air that is useful for various tasks. They work by compressing air inside the storage tank and releasing it at high power through the hose and any other attachments. The compressor is made up of various components, including the three primary parts:

- Motor

- Pump

- Storage tank

Understanding how each component works individually, as well as how they work together, will help you diagnose and repair any issues that may arise with your air compressor.

Common Air Compressor Problems

Air Leaks

One of the most common issues with air compressors is air leaks. Air leaks in hoses, pipes, tank valves, and even in the tank itself will result in your compressor not functioning correctly. To check for air leaks, turn your compressor on and listen for any hissing sounds. Another way to check for air leaks is to apply a soapy solution on the leaky area, and if bubbles form, then there is a leak.

Low Air Pressure

Low Air pressure is another common problem that users face with air compressors. There could be many reasons for low air pressure, such as a damaged valve, pressure switch, or tank, resulting in your compressor not producing the required air pressure. Checking for any damaged components, clearing the air filter, and adjusting the pressure switch could fix low air pressure issues.

Overheating

If your air compressor becomes too hot, it can stop working. This could happen due to several issues, such as a lack of proper ventilation or a malfunctioning thermal overload. An easy way to avoid overheating is by ensuring the compressor has sufficient ventilation and is placed away from any heat sources.

Tripped Circuit Breaker

If you connect your air compressor to an inadequate power supply or overload it, it will cause a short circuit and trip the circuit breaker. To solve this problem, switch off the compressor, unplug it, let it cool down, and reset the circuit breaker.

Compressor Won’t Start

If your air compressor won’t start, there are several simple solutions, such as checking the power supply, resetting the pressure switch, or replacing the capacitor.

Compressor Cycles Too Often

If your air compressor is cycling too often, it could be because the pressure switch is set too high or because the tank size relative to the demands is too small. Primarily, you can replace or adjust the pressure switch or switch to a larger capacity tank.

Easy Fixes for Air Compressor Problems

Fixing air compressor issues doesn’t always require expert skills or expensive tools. Easy fixes, with some basic items, could be helpful, such as tightening loose connections, replacing worn-out O-rings, cleaning the air filter, etc.

Air Leaks

Air leaks can sometimes be quick fixes. Tightening loose valves or connections or replacing worn-out O-rings could eliminate the problem.

Low Air Pressure

If the regulator or gauge shows low air pressure, cleaning or replacing the air filter could enhance air flow and pressure. Sometimes adjusting the pressure switch serves the purpose.

Overheating

Overheating could lead to severe problems, but minor overheating issues can sometimes be fixed by placing the air compressor in a well-ventilated or open location.

Tripped Circuit Breaker

Resetting the circuit breaker is often simple. When the breaker trips, turn off the compressor and allow it to cool off. Then proceed to reset the breaker.

Compressor Won’t Start

The main reason for a compressor not to start is because of an electrical fault. Check the power cord for damage, ensure the power supply is adequate, and replace the capacitor if necessary.

Compressor Cycles Too Often

Frequent cycling could wear out the compressor components prematurely or lead to compressor failure. Use an external air pressure regulator or reduce the demands on your compressor to fix this issue.

Conclusion

Air compressors are versatile tools used for various tasks, and they need to function correctly to achieve optimal performance. Remember to use precautionary measures when handling these tools, and always keep your air compressor well-maintained. Troubleshooting air compressor problems can be done quickly by following the simple steps outlined in this guide, enabling you to continue using your air compressor as desired.